After months of major redevelopment in terms of quality standards and food safety, Newrest unveils an innovative, high-performance and sustainable catering unit dedicated to the airline sector. Immersion in its premises on the airport zone.

Delphine Raimond

“From the outset, our ambition has been to make the necessary investments to significantly improve the sustainability of our operations. It is our responsibility to provide an efficient and safe working environment for our team”, says Olivier Sadran, Co-Chairman and Founder of the Newrest Group, before reiterating the Group’s commitment to the well-being and quality of work of its employees, and expressing his sympathy for those on the production line who had to continue their operations under difficult conditions.

The tour begins with an impressive historical frieze featuring more than a dozen key dates in the group’s development, from its creation in 1996 as Catair to the present day. Exponential growth has made Newrest a leader in the catering market, operating for some of the world’s biggest companies and airlines. The completely renovated premises house a unique “forward motion” circuit, from the receipt of goods, to the meticulous composition of trays, installed on the trolleys, themselves sealed, for on-board delivery, via refrigerated storage adapted to the foodstuffs, disinfection, cleaning, preparation and the dishwashing area, re-equipped with ultra-efficient washing equipment. The production line – which runs continuously, except for a night shift devoted to cleaning the entire unit – reflects a perfectly controlled process. As Aurélie Gueguen René, COO Asia, Pacific, Middle East and Africa, explains: “It’s the partner company that defines the service; we’re there to carry it out properly and in compliance.

From the daily supply area, raw materials are dispatched and stored in various refrigerated chambers, with temperatures adapted to each type of merchandise. We discover the storage of fruit and vegetables, eggs – shells and liquid, for bakery and pastry preparations – and dairy products… a succession of Ali Baba’s caves!

Next comes the disinfection area, followed by the production area, following the path from dirty to increasingly clean. Here, vegetables are cleaned, cut up and prepared… Aurélie shows us the knife box, which will be closed and padlocked as soon as the workers leave the area; air safety is a must! I close my eyes and find myself in my grandfather’s vegetable garden. A distinction is made between fruit and vegetables, to prevent some of the latter, which may be earthy, from carrying any contamination.

In the bakery, a production run is underway: pastry chefs are making cinnamon rolls and danishes for British Airways. Vanilla muffins, chocolate muffins and other freshly baked viennoiseries wait to fill the trays, while mouth-watering tarts get ready for the oven. Further on, bread rolls are packaged differently: in bags of several to be reheated in business class, in individual packages for economy class. In the baking area, the oven rings, the gourmet aromas torturing my stomach.

We enter the “cold kitchen” and sandwich shop, where staff are busy packing food into trays or plates (according to company instructions). The presentation is neat and colorful, and each preparation – salads, assorted cheeses, sliced, weighed and calibrated salmon rolls… – is a fresh delight! As the “hot kitchen” was in its final phase of construction at the time of our visit, we won’t have the chance to discover it – unless, of course, it is, as lunchtime approaches, treading through the kitchens, where everything is homemade and prepared to the highest standards, is a real torture!

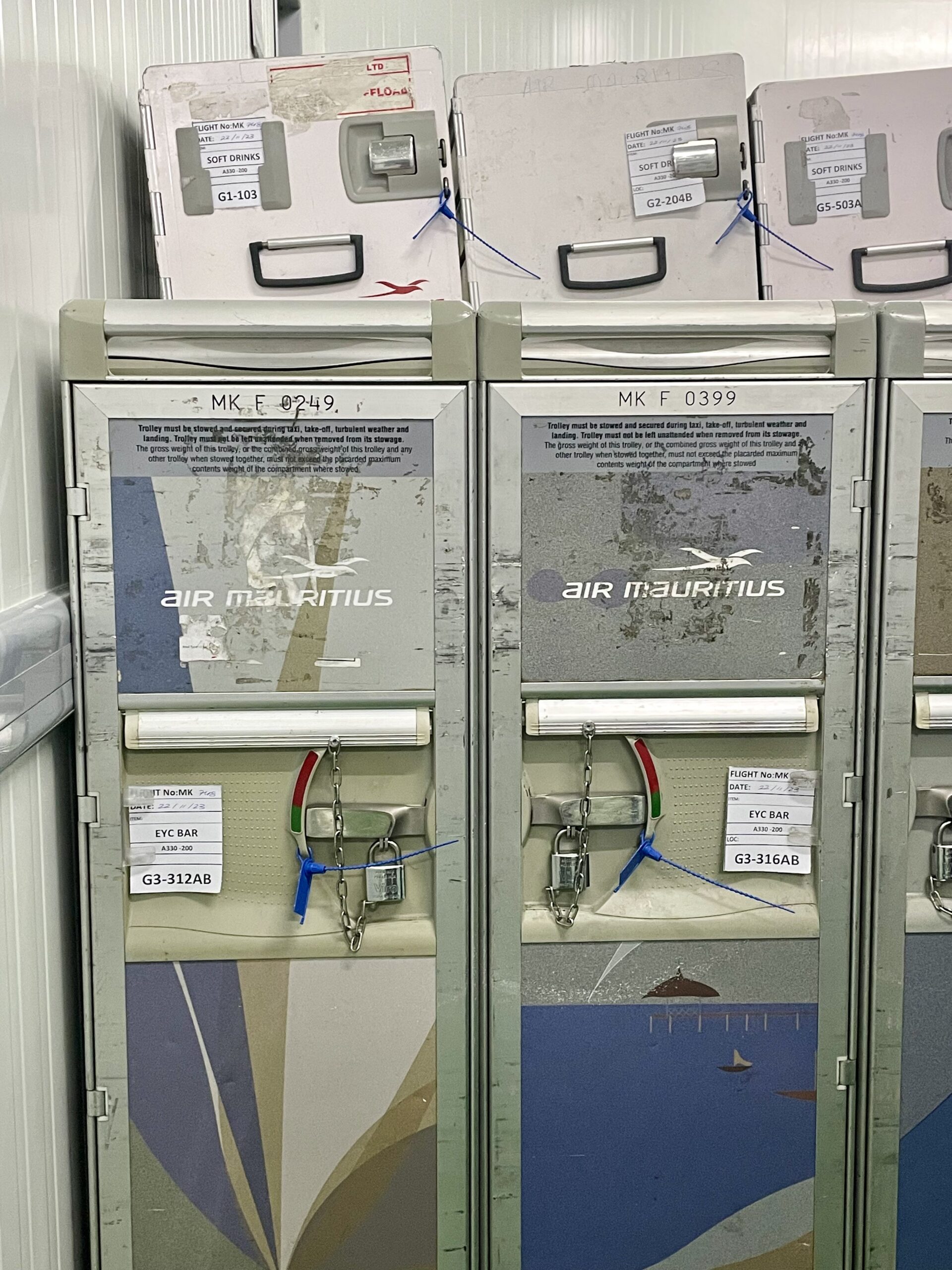

The meal tray assembly area completes the production circuit. The trays are positioned on a man-height industrial conveyor belt, with each employee adding a component, until they are covered at the end of the rail with a plastic film or lid, according to the company’s specifications, before being installed on the trolley. Sealed, the trolleys are then ready for take-off.

The unit also features a huge crockery storage room, since each company has its own equipment, which it supplies to Newrest, which is also responsible for cleaning. Before the dishwashing area (the equivalent of a small sauna!) and dish storage, a small team is in charge of a task as meticulous as it is essential in on-board catering: putting together the famous pouch containing cutlery, seasoning, napkins and so on. Seven items, for example, have to be inserted into each Air Mauritius container, manually and one by one! As Aurélie points out, a single little mistake here can disrupt an entire in-flight service and waste crew members’ time. It’s a delicate and demanding task.

I’m very pleasantly surprised by the unit’s level of quality, both in terms of the products and the execution of each operation on the production line. It’s clear that Newrest has done everything right. Renovation work, involving an investment of 7 million euros, has totally transformed the facilities, with the aim of limiting environmental impact. The NEMO GREEN digital platform makes it possible to closely monitor the energy consumption of equipment, so that corrective measures can be taken if any discrepancies are identified. As part of its sustainable approach, the company has installed water heaters and solar panels for green energy, a building cooling and waterproofing system, a non-slip epoxy resin floor, side safety rails covering the corridors and protecting the walls from cart impacts, a cryogenic cycle powered by refrigerant gases, as well as initiatives to reduce food waste (with rationalized production), water consumption, waste, etc. Six new catering trucks have been ordered; two have already arrived from South Africa, the other four will be delivered at the end of January 2024.

When asked about future contracts for the Newrest group in Mauritius, Aurélie is not worried and simply replies, “When you deliver quality, customers come to you!”